Thermal Energy Meter

The HFM11 is a miniDAS-based commercial-grade thermal energy meter (or BTU meter) capable of measuring heat flows

through devices such as hot water heaters, heat exchangers, waste-heat recovery units, desuperheaters, or

solar heating systems. Where heat is added to or taken from a fluid, the energy meter can measure the amount of heat exchanged. Heat is

measured by connecting temperature sensors to the fluid inlet and exit pipes and by inserting

a volumetric fluid flow sensor in either the inlet or exit pipe. The meter measures the fluid temperature difference between

the inlet and exit and multiplies it by the fluid flow rate and a thermodynamic coefficient. The result is the energy flow rate. This rate

is accumulated as the total heat flow.

The HFM11 is a miniDAS-based commercial-grade thermal energy meter (or BTU meter) capable of measuring heat flows

through devices such as hot water heaters, heat exchangers, waste-heat recovery units, desuperheaters, or

solar heating systems. Where heat is added to or taken from a fluid, the energy meter can measure the amount of heat exchanged. Heat is

measured by connecting temperature sensors to the fluid inlet and exit pipes and by inserting

a volumetric fluid flow sensor in either the inlet or exit pipe. The meter measures the fluid temperature difference between

the inlet and exit and multiplies it by the fluid flow rate and a thermodynamic coefficient. The result is the energy flow rate. This rate

is accumulated as the total heat flow.

This meter has two energy measurement systems. It uses temperature inputs 1 and 2 for the first system and

inputs 3 and 4 for the second. Similarly, flow sensor input 1 is used by the first system and input 2 by the

second. The terminal connectors for these sensor inputs are together in one terminal strip at the lower end of the

circuit-board.

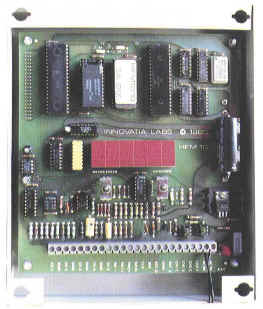

The single-board, 6502-based dual thermal energy

meter has a menu-driven, Innovatia-style user interface. This front-panel consists of two two-way switches (that can be pushed

either up or down) and a six-digit LED display. The switch-mouse (4 switches: MENU (Esc), Enter, Up, Down) runs the

menu tree on the display and numeric entry. The meter provides a menu of different functions that can be selected for displaying

quantities (such as total accumulated heat) or setting parameters (such as flow sensor scale factors).

When installed and operating, the meter samples the four temperatures

once every six seconds and the flows every second. It then calculates the amount of heat that flowed by in the fluid that second and adds it to the

When installed and operating, the meter samples the four temperatures

once every six seconds and the flows every second. It then calculates the amount of heat that flowed by in the fluid that second and adds it to the

accumulated total. Also, the total volume of fluid is updated. During operation, several different system quantities (such as fluid flow rate or

temperature differences) can be monitored without affecting heat or fluid volume accumulation.

While the meter is operating, it sends pulses out the datalogging outputs, one for each energy system. These can be sent directly to most data

recorders or to a computer with a compatible interface.

This meter is auto-calibrating. Every six seconds it spends two of them calibrating itself against frequency and resistance standards on the circuit-board. These standards are accurate for the life of the instrument and

eliminate costly periodic calibration or accuracy degradation between calibrations.

Thermal Energy Meter Designware

This is a limited-edition item because the discrete 6502-based design is generally considered obsolete. Assistants can, however, save much effort in porting the meter, or functions of it, to another microcontroller from the existing designware.

The dual thermal energy meter designware includes:

|

Manual containing chapters on: |

1 Introduction

2 Installation

3 Operating Instructions

4 Specifications

5 Theory of Operation

6 Service Information

|

Schematic diagrams | |

|

EPROM firmware files, for English and metric energy units, and for desuperheater applications | |

|

Applications notes |

Several LE product units are available for $350 each. Three are in NEMA1 (drip-proof) enclosures for outdoor installation for $400.

This is not an active Innovatia project. The HFM11 has been modified to become the miniDAS which is used only in Limited Edition prototype units of other instruments. The HFM11 Manual is available to Innovatia Assistants.

HFM11 Designware is also available.

![]()